SF6 Gas Use in Electrical Applications

Rapidox SF6 Gas Analyser

What is it, where, how & why it is used – The science bit…

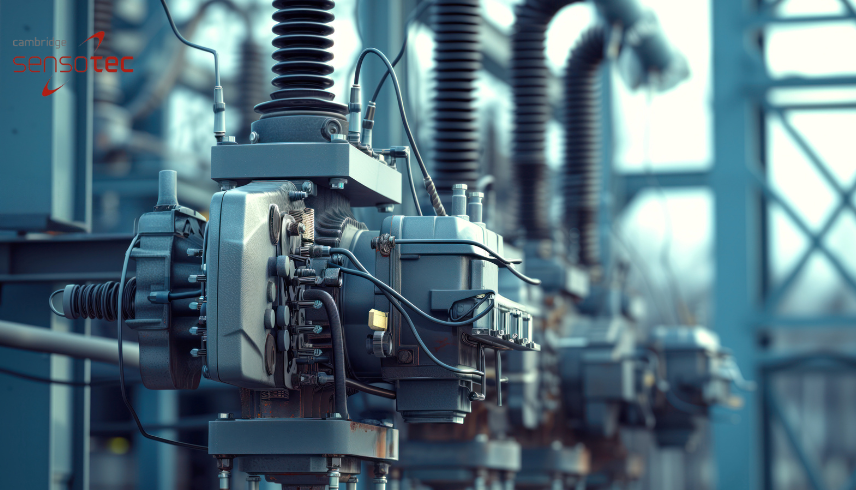

Commonly used in electrical switchgear, transformers and substations as an electrical insulation, arc quenching and cooling medium, Sulphur hexafluoride (SF6) is a man-made gas comprising of one sulphur and six fluoride atoms. It is chemically stable, non-flammable and highly electronegative, with an excellent dielectric property of approximately 2.5 times more than air.

Electrical arcs can be caused within electrical power systems such as switchgear and the high electronegativity and heat transferring properties of SF6 means that it is able to absorb the electron energy and lower the arc temperature. Combining SF6 gas and free electrons effectively prevents electron avalanches and flashovers.

SF6 partially decomposes whilst under the influence of electrical discharges, and oxygen, moisture, and decomposition products such as sulphur dioxide may be created. Unlike other insulating mediums, SF6 gas has the unique ability to ‘self-heal’ after the discharge. This is one of the reasons for its widespread use within the electrical industry.

Keep it safe, keep it green – The Safety bit…

Regular analysis of SF6 gas is essential. Regular periodic servicing must be carried out throughout the lifetime of the equipment. This ensures the protection of personnel and machinery.

An international agreement between nations called the Kyoto Protocol came into force in 2005. It commits its parties by mandating country-by-country reductions in greenhouse gas emissions. Due to its chemical stability, SF6 gas has the potential to remain in the atmosphere for thousands of years. So, the agreement has identified it as a greenhouse gas with a limitation as to the amount that can be released into the atmosphere.

Our SF6 gas analyser – The manufacturing bit…

Cambridge Sensotec has developed a new Mark II Rapidox SF6 6100 gas analyser featuring a pump back gas return function.

It extracts the SF6 gas from equipment such as Gas Insulated Swichgear (GIS) and simultaneously analyses all measured gases. It then pumps it back at the same pressure as used within the electrical equipment by using a powerful 35 bar compressor. A vacuum purge cycle and gas storage system ensures no air is allowed to contaminate the gas sample and no SF6 gas is permitted to escape during the testing period.

Rapidox uses high-precision infrared (IR) sensor technology for the analysis of SF6 gas. Decomposition products sulphur dioxide (SO2) and moisture (H2O) can also be measured by the Rapidox. Additional sensors for gases such as carbon monoxide (CO), hydrogen sulphide (H2S) and hydrogen fluoride (HF) are also available.

The Rapidox SF6 6100 pump back gas analyser has been developed as a truly portable field instrument with features such as:

- An inbuilt microprocessor operated by a 7” colour touchscreen

- The ability to store 12 months continuous data

- An in-built printer

- Pre-loaded IEC and CIGRE test parameters

- The ability to customise test parameters

- An 8-hour lithium ion battery

- Robust IP66 Peli case

- Multi language capability

- Between 2-8 minute testing options

- Up to 8 gas bespoke build capability

- Teamviewer connection for instant service

- 35 bar gas inlet

For further information regarding this or any of our gas analysis products, please contact us on +44 (0)1480 462142, or email us at sales@cambridge-sensotec.co.uk.