Introduction:

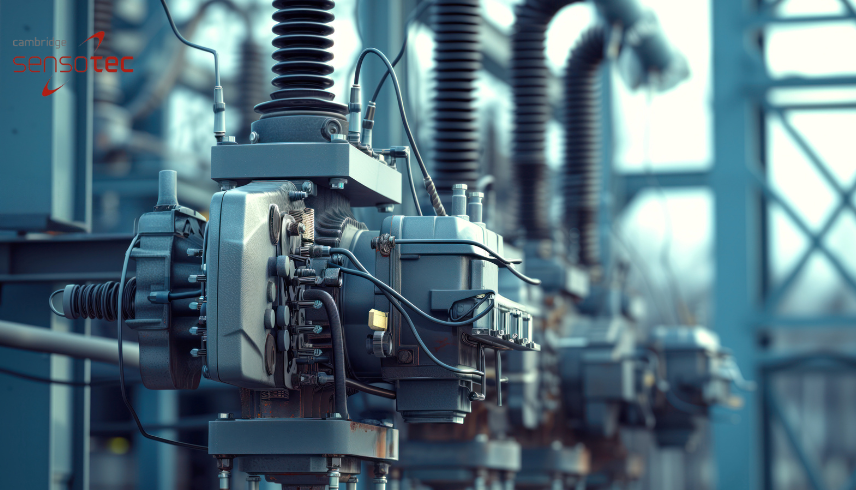

In the intricate world of electrical switchgear maintenance, ensuring the safety and reliability of equipment stands as a non-negotiable priority. At the heart of this effort lies SF6 gas, a crucial insulating medium that plays a pivotal role in safeguarding electrical systems and personnel. Delving deeper into the subject, this blog post sheds light on the indispensable nature of SF6 gas analysis and its impact on equipment safety and longevity.

Understanding SF6 Gas Analysis:

SF6 gas serves as the lifeblood of electrical switchgear, facilitating the smooth flow of energy while mitigating the risk of electrical faults. However, the integrity of SF6 gas can degrade over time, potentially jeopardizing equipment performance and safety. SF6 gas analysis emerges as a vital tool, offering invaluable insights into crucial parameters such as gas purity, moisture levels, and decomposition byproducts. By effectively monitoring SF6 gas properties, maintenance teams can stay ahead of potential issues and ensure uninterrupted operation.

Benefits of SF6 Gas Analysis:

The benefits of regular SF6 gas analysis are manifold. By proactively monitoring gas properties, maintenance professionals can detect and address issues before they escalate, thus preventing equipment damage and minimizing downtime. Furthermore, accurate SF6 gas analysis data serves as compelling evidence of equipment integrity and safety compliance, bolstering confidence in regulatory inspections and audits.

Cambridge Sensotec Solutions:

Cambridge Sensotec stands at the forefront of SF6 gas analysis solutions, offering advanced analysers tailored to the unique requirements of electrical switchgear maintenance. Our cutting-edge technology empowers maintenance professionals with precise measurements and actionable insights, enabling them to make informed decisions and optimise equipment performance. With Cambridge Sensotec’s comprehensive SF6 gas analysis solutions, the journey towards enhanced equipment safety and regulatory compliance becomes both achievable and efficient.

Conclusion:

In conclusion, SF6 gas analysis is not merely a maintenance task but a cornerstone of equipment safety and reliability in electrical switchgear installations. By leveraging the power of data and technology, maintenance teams can proactively monitor SF6 gas properties, detect anomalies, and take timely corrective actions. With Cambridge Sensotec’s expertise and innovation, safeguarding electrical switchgear with SF6 gas analysis becomes a streamlined and effective process.

For more information on our Rapidox SF6 gas analysis solutions, contact Cambridge Sensotec today and embark on the path to enhanced equipment safety and reliability.

Further Reading: